PRODUCTS

Product Category

KB0060-1

key word:

vegetable dehydrator/food drying machine

Category:

Tel:008613713382873

Wechat/Whatsapp: 008613713382873

Email:dana@kboen.com

Description

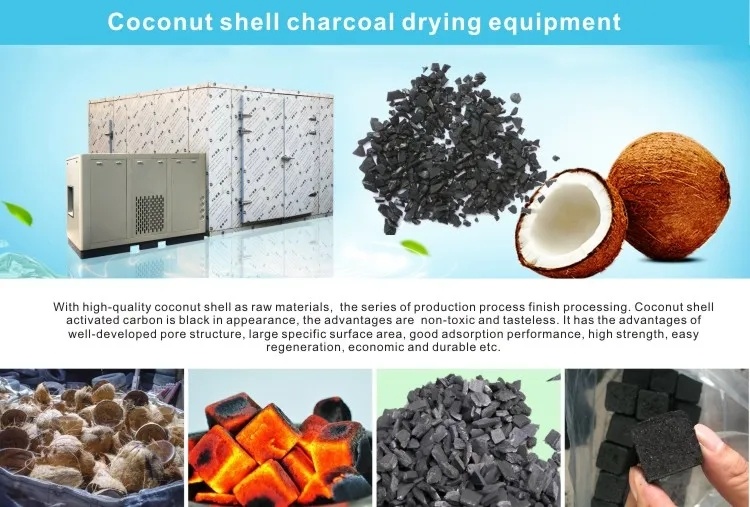

Product Description

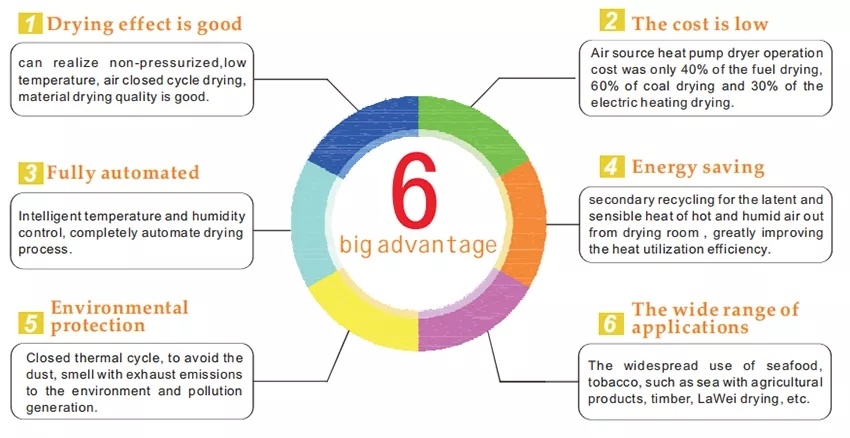

System advantage

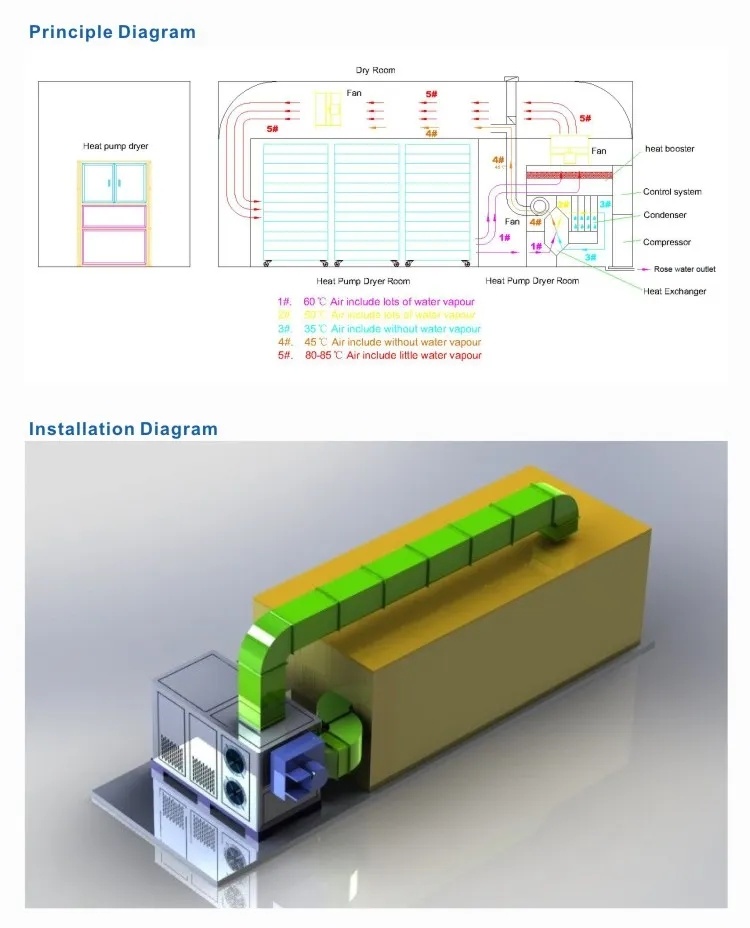

1>> Super high temperature:the temperature of output wind reach to 85 degrees, after 10 years of testing the market, the first investment in the use of the industry.

2>> Uniform material: after the condensation,the high temperature wind through each layer material, so that the material is evenly heated dehydration.

3>> Wide range of application: agricultural products, industrial products, seafood and other more than 20 industries.

4>> Super high energy saving: the use of heat recovery technology, based on the automatic humidity of the baking room humidity, energy efficiency in more than 70%.

5>> Low carbon emission reduction: environmental and no pollution, no waste water, waste gas and waste residue discharged during drying process.

6>> Design concept: integrated control system and baking room, no need to install, just to connect the power to start using .

7>> Automation control: the use of integrated control system, man-machine interface, automatic control without personnel on duty.

8>> Equipment energy consumption: full load power 3.7KW, equipped with 6 square wire, theoretical drying weight 400 kg.

9>> The gospel of entrepreneurs: you can start a business, you can help people to process.

| Technical Parameters | ||

| Model No. | Unit | DF-C-12 |

| Power Supply | 220V/50Hz | 380V/3/50HZ |

| Dryer Heating capacity | KW | 28KW(70℃) |

| Rated Input power(Compressor) | KW | 11.4KW |

| Rated Input power(circulating fan) | KW | 0.6KW(2pcs) |

| Total Power | KW | 12KW |

| Rated Input Currents | Amps | 26A |

| Compressor | 3HP scroll | |

| Compressor quantity | Pcs | 4 |

| Refrigerant Type | special refrigerant | |

| Refrigerant charge | kg | 8kg |

| Circulation fan volume capacity | m3/h | 5000-8000 M3/h |

| Circulation fan speed | RPM | 2800R/MIN |

| Evaporator | Copper tube,Aluminum fins | |

| Condenser | Copper tube,Aluminum fins | |

| Ambient temperature | ℃ | 5 to 45 |

| *Maximun/rated temperature | ℃ | 85/80 |

| *Noise | dB(A) | 55 |

| *Chamber dimension(LWH) | mm | 2750*2300*8200 |

| Exhaust maximun temperature | ℃ | 115 |

| *Exhaust pressure | Mpa | ≤2.35 |

| *Return air pressure | Mpa | ≤0.03 |

| *Net weight | Kg | 350 |

| Application type | Indoor&Outdoor | |

| Container loading | 30 sets | |

Application

Widely used to drying fruit,vegetable,herbs,meat,seafood,etc.Such as litchi,honeysuckle,daylily,beef jerky,mushrooms,blueberry,

medlar,jujube,walnut,plum,tea,apricot,raisin,bacon,suasage,small shrimp,rice,etc.

Online Message

Thank you for your attention to us. If you have any needs or comments, please leave us a message.